In a world of tight schedules and complex builds, you need a detailing team that eliminates clashes and delivers certainty upfront. Our detailing team turns design intent into precise 3D models that match exactly what gets built in the field. We use real-world components to create prefabrication-ready layouts and streamline your installation. With one of the largest MEP detailing teams in the Pacific Northwest, we help you build smarter, faster, and with fewer surprises.

Detailing

Virtual Planning, Real Outcomes

Constructability & Operational Quality

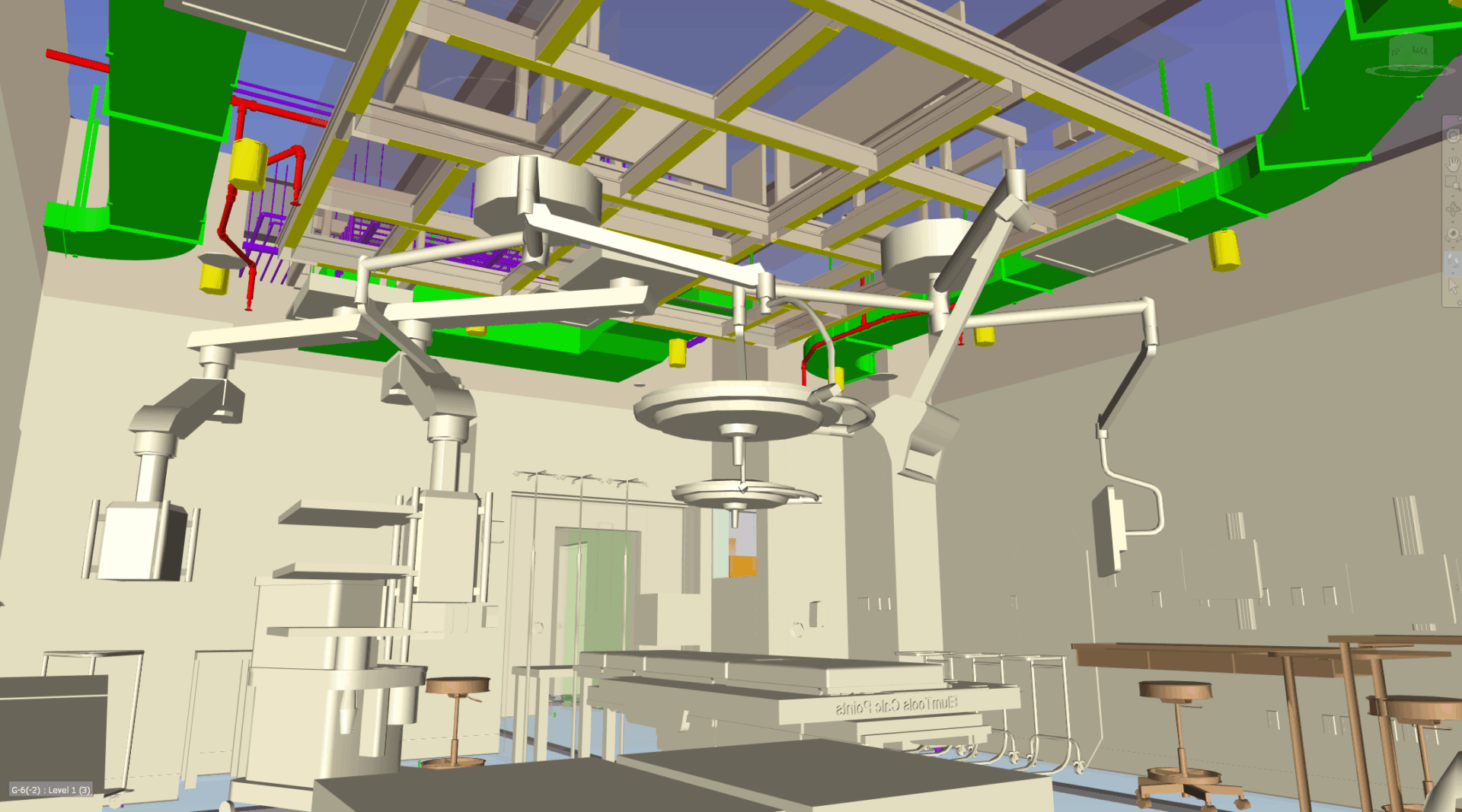

Our process ensures that designs are highly constructible and practical for long-term operation and maintenance. Our detailed pre-planning, which involves input from engineers to field foremen, means your equipment will be accessible and serviceable, avoiding future maintenance headaches.

Accelerated Timelines & Cost Efficiency

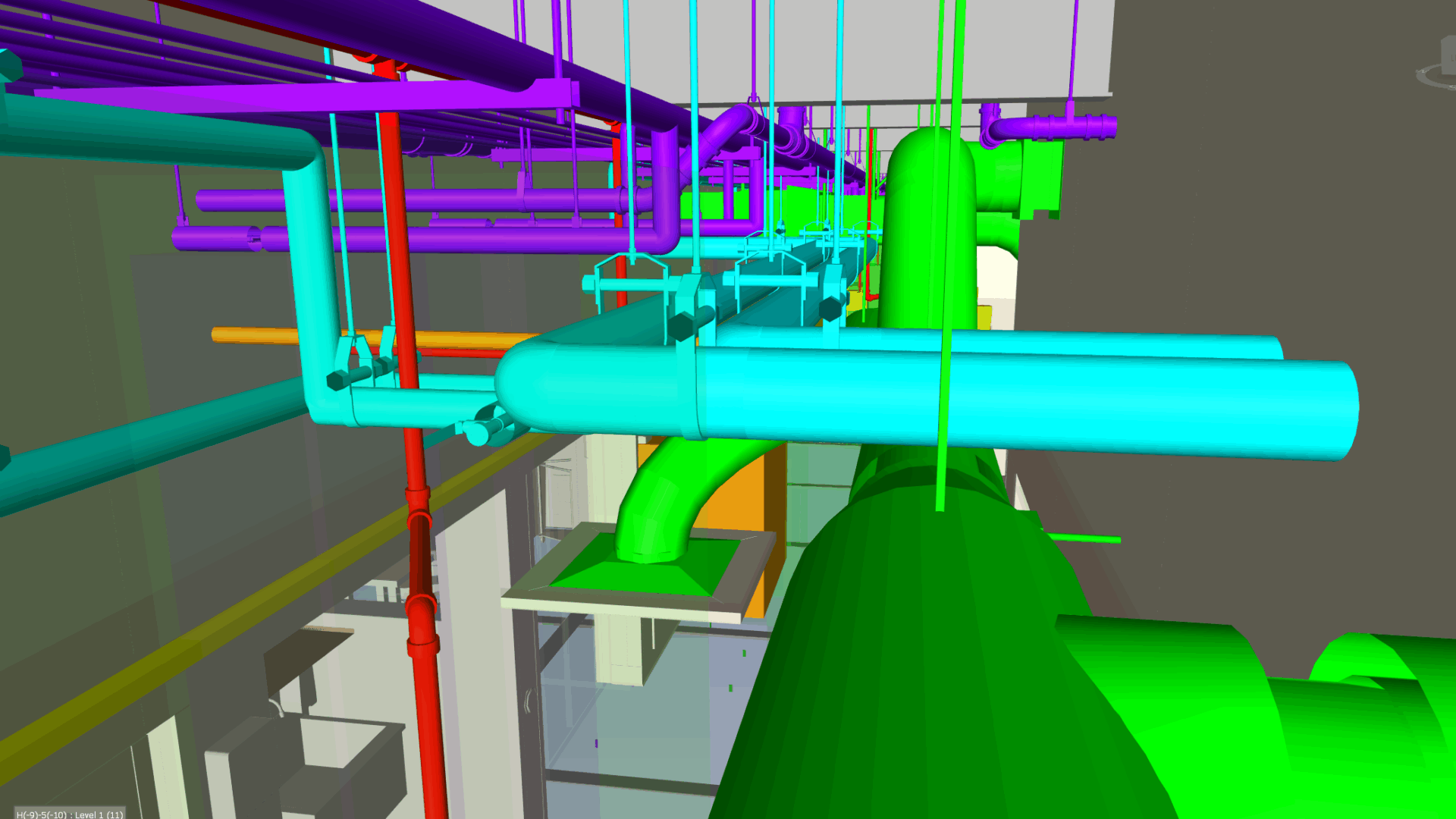

By designing and optimizing systems in a 3D environment, we can extensively prefabricate components and assemblies in our controlled shop environments. This shifts labor to a more efficient setting, leading to compressed schedules, enhanced safety, and ultimately, significant cost and time savings for your project.

Proactive Conflict Resolution

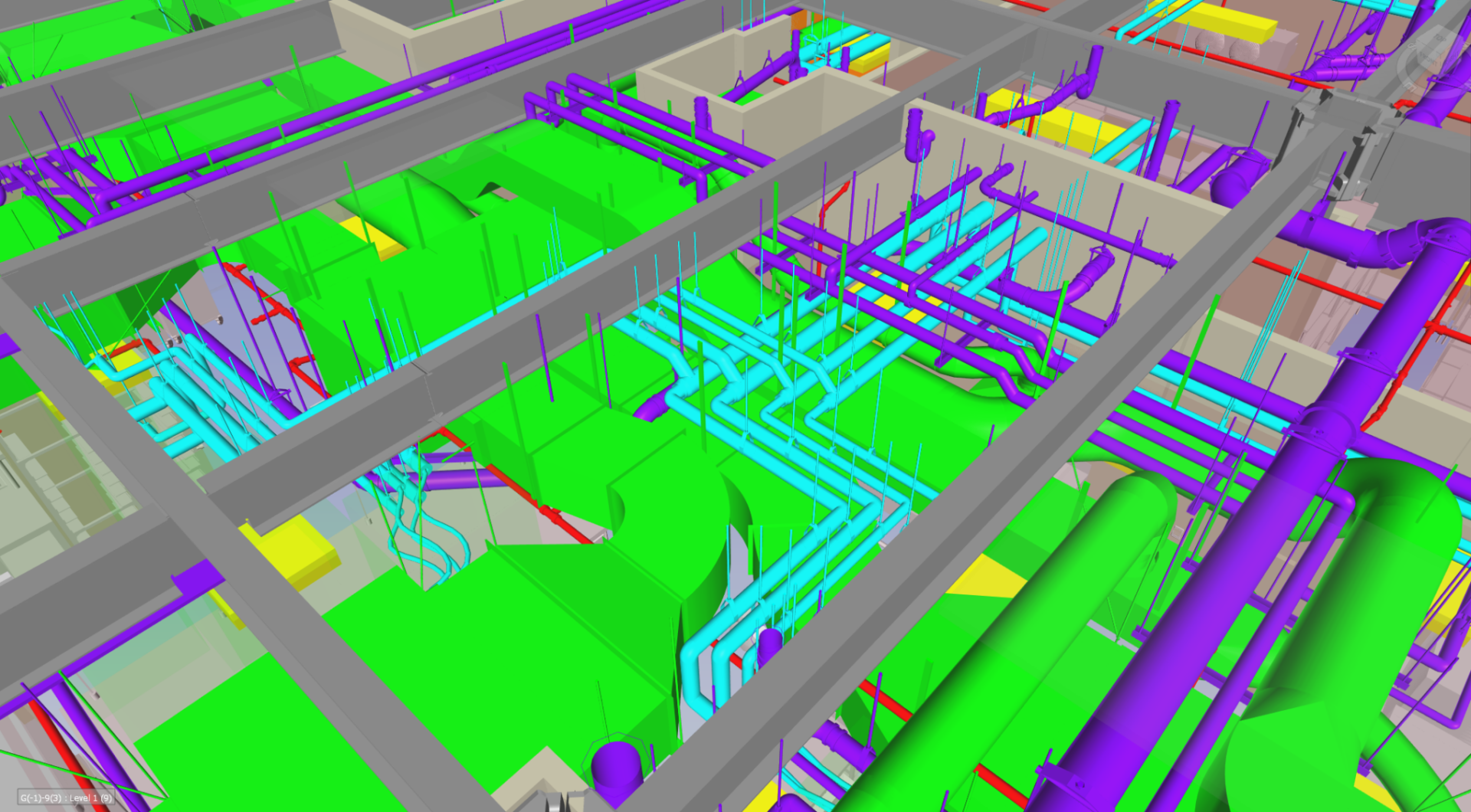

In creating a fully rendered vision of your building’s mechanical systems, we identify and resolve potential conflicts with other trades in a digital environment before construction even begins. This foresight drastically reduces costly field changes, delays, and rework.

Unparalleled Transparency

We can provide you with a clear, visual understanding of your mechanical systems’ layout before installation. This enhanced transparency means fewer surprises and greater predictability throughout the project lifecycle.